Humans have aimed for perfection in manufacturing since the origins of commerce but the general perception would say otherwise. Have you tried asking close friends: are your new appliances more or less reliable than a decade ago? Would you be shocked to hear their experiences?… or perhaps, not so much so. Are we turning old and grumpy? Is planned obsolescence a real world phenomenon? Is it a carefully planned manufacturing strategy? Or what is actually going on?

Sitting atop the HIFI system of one of the authors of this post is a 26 year old Minidisc player from SONY, immaculate and fully functional. By contrast, part of this article has been typed in a buggy keyboard of a 3 year old top-of-the-line laptop from DELL (which, by the way, has already been serviced multiple times).

Total quality management, ISO9001, regulatory certifications, robotics, computer aided design, industry 4.0… are many of the initiatives aimed at improving quality, and yet few would argue that products have lately taken a hit in terms of reliability and durability, which seems contradictory by most standards.

There are multiple reasons why this quality paradox exists. In this post, we would like to explore some of them, in particular, the connection that exists between worker conditions, cost of quality and final product quality. We find this a compelling reflection to make because worker enablement and quality improvement are at the core of nFlux’s mission. Please read on and let us know what you think!

The history of Quality Management: The quest for Perfection

Before we dive into the reasons for the quality paradox, let us take a few steps back and walk through the history of Quality. But if you are not in a mood for a history lesson, feel free to jump to the Quality Paradox section.

“Those that fail to learn from history are doomed to repeat it.”

Winston Churchill

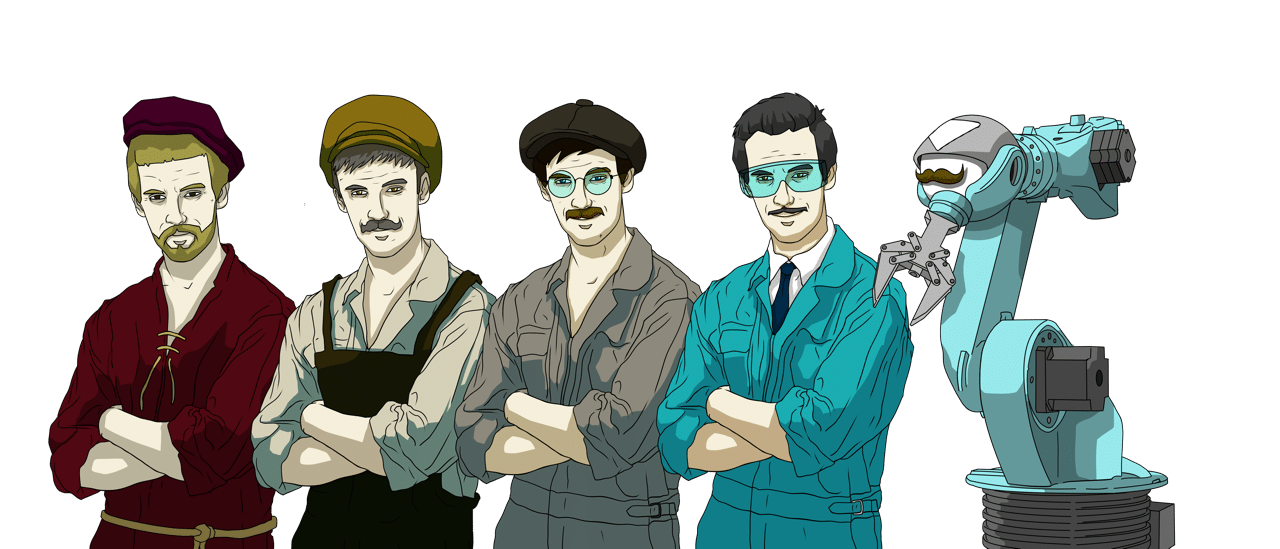

As the American Society of Quality (ASQ) explains in their article on The history of Quality, the guilds and unions of craftspeople were already establishing quality parameters for products and services as far back as the Middle Ages. Inspection committees would mark goods with symbols to certify the quality of the products. Craftspeople themselves often placed a second mark on the goods they had produced, and over time, their marks came to be a sign of the craftsman’s good reputation and personal brand.

Think about furniture makers, luthiers, blacksmiths, artisans that would dedicate their entire life to mastering the craft of producing one type of good or service. These craftspeople would pass on their knowledge to their next of kin which would eventually perfect the craft over generations. These were the original manufacturing professionals that could feel quality with all their senses: they could see it, smell it, touch it and even feel it within their souls.

“Craftspeople were manufacturing professionals that could feel quality with all their senses.”

The marks that craftspeople would stamp or etch on their products served as a proof-of-quality for customers until the advent of the Industrial Revolution in the early 19th century when craftspeople started working as mere members of a production line and were displaced by large high volume factories. The Industrial Revolution divided the craftspeople’s trades into specialized tasks to increase consistency and productivity. By increasing productivity, the volumes of goods produced became larger and the overall cost of production became smaller, helping to make the goods more affordable for the general benefit of society and humankind.

But this change also forced craftspeople to become factory workers, and shop owners to become production supervisors. Workers weren’t recognized by their craft but just by the raw working power of their hands and overall output. The old craftspeople lost their sense of empowerment and accountability when producing their crafts and became just workers. As such, it became the supervisors’ responsibility to look after quality by inspecting and detecting the defective parts for either rework or to be marked as scrap.

Late in the 19th century, factories adopted the Taylor system, created by Frederick W. Taylor, to increment the productivity of the plant, by assigning factory planning to specialized engineers and using craftspeople and supervisors as managers who executed the plans defined by the engineers further separating crafts decisionmaking from the manufacturing workers. Taylorism (Taylor system) boosted productivity to new heights but, as the ASQ reflects, it had an increasingly negative impact on quality and more defective products started reaching customers.

During World War II, this laissez-faire approach to quality had to change. Quality became a critical element in the manufacturing of military products. Unsafe military equipment was unacceptable and manufacturers were forced to inspect virtually every unit to ensure that the quality standards were optimal. To control quality without compromising productivity, the plants started using Sampling Inspection. With this method, instead of checking each unit, factories would select a percentage of random units as a sample, to statistically control quality while containing the overall cost of quality. Walter Shewhart, the grandfather of Total Quality Management, defined a set of standardized sampling tables which would help manufacturers determine the appropriate sampling frequencies to meet the intended levels of quality.

But after World War II, a huge revolution happened as it relates to quality in manufacturing led by Japanese manufacturers. Toyota was the torch-bearer. These Japanese industrial companies crystalized the theories of quality gurus Dr. Joseph M. Juran and Dr. W. Edwards Deming in combination with their deep ancestral culture for quality craftsmanship to completely disrupt the world of manufacturing. Dr. Juran and Dr. Denim advocated for a more robust, structured, and logical approach to quality management rather than simple end-product inspection. This involved improving all organizational processes through the people who used them and implementing checks and controls much earlier in the production process. Japanese products became known for their unrivaled quality standards, forcing manufacturers in other parts of the world to react (remember the Minidisc player we mentioned earlier?).

U.S. manufacturers, for example, responded to Japanese competition with price reductions strategies but as years passed, price pressure became unbearable and forced quality to become a key concern of American industry. Dr. Deming and Dr. Juran, helped then US manufacturers to adopt their Total Quality Management (TQM) culture. TQM is a management system that requires everyone within the organization to focus on long-term success through customer satisfaction and operational excellence.

Now fast-forward to the 21st century, and quality management has continued with the introduction of standards such as ISO 9001 or industry specific ones such as TL9000 or AS9000, which extended TQM to also take into account the importance of risk management. Six Sigma, a methodology for process improvement developed by Motorola, is often used together in the context of quality management for continuous improvement.

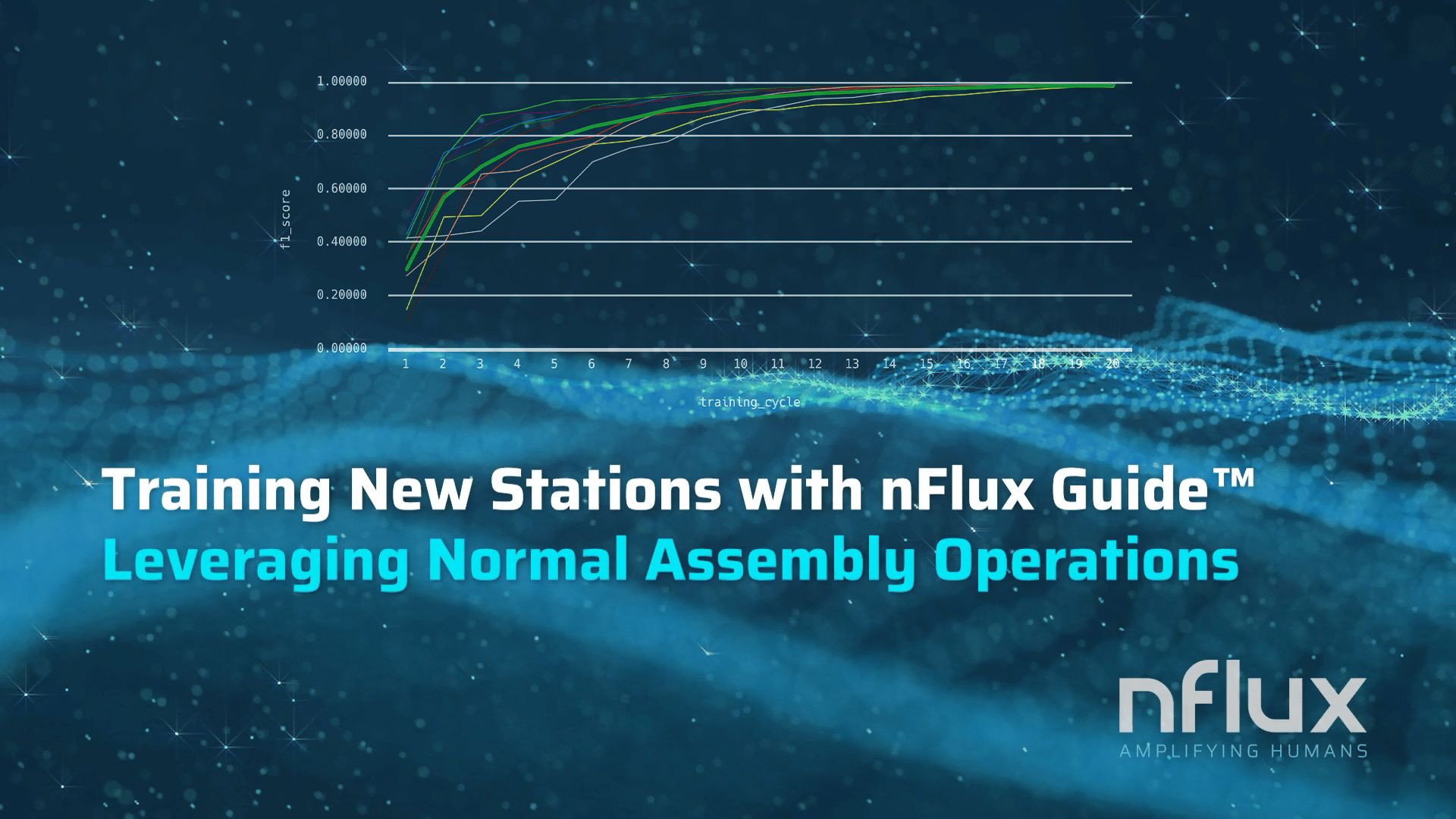

Not only has quality management techniques continued to improve, but the reliability and precision of industrial manufacturing processes have also been, and are subject to continuous evolution. With the incremental adoption of robotics and automation, which brings an increased level of precision and reliability, and with the usage of modern technologies, such as AI and computer vision to predict machine failure or to do error detection, the possibilities to increment quality are continuously expanding.

One could argue that the Quest for Perfection is not only not over, but now intensifying. Quality continues to be a paramount concern in manufacturing, commerce and the economy at large. And yet, we all have heard and suffered examples of poor quality in the goods we have bought to a point that there is a widespread feeling that quality instead of moving forward is in actuality moving backward. Why is this?

The Quality Paradox: Why the more we search for it, the further away we are?

The TL; DR (too-long, didn’t-read) answer is that quality is only a major concern in manufacturing and in commerce from a philosophical perspective. In reality, the ultimate true concern is price for consumers and margin for manufacturers. The root causes for this are probably a little more nuanced and warrant a longer reflection.

Industrial Manufacturing stole the soul of craftsmanship

In the transition to factory-based production, manufacturers have been mainly concerned with improving economic productivity. Yielding a larger number of products at a lower cost, to be more competitive, and to generate more business. Many manufacturers have seen technology as a replacement for humans in order to reduce the costs of production. They made their bets that by designing and implementing strong procedures and maximizing the use of automation, the level of quality would be implicitly improved. In a way, there have been some extreme industrial manufacturers who have devolved craftspeople to become mere workers. These former craftspeople would become inconvenient, yet-to-be-robotized, manufacturing mules that would be focused on very specific tasks which they could master and repeat relentlessly and endlessly.

Close your eyes and envision a luthier (a craftsman specialized in creating musical instruments) meticulously working in his workshop. A venue full of precision tools and timber. Picture the luthier knocking on a plate of wood and hearing its sound quality, smelling it to evaluate the level of humidity, touching it with the tips of his fingers to sense the finish in the sanding. Remember that this luthier has been all his life mastering the craft of making musical instruments, probably taught by his parents. Being luthier is not a job, it is a way of living and being.

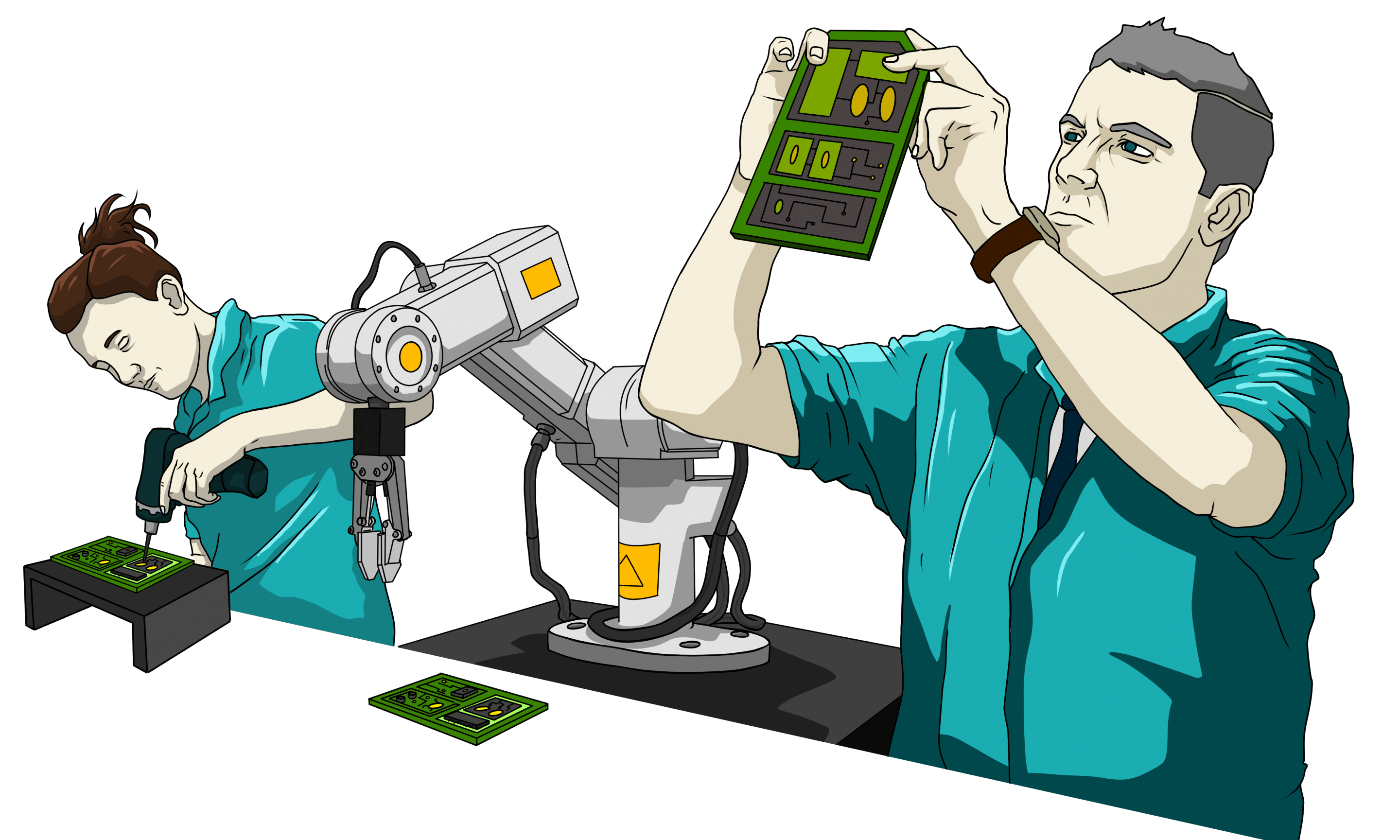

Now open your eyes and see a worker relentlessly assembling products in a production line. Industrial manufacturing has strived to maximize worker’s productivity-many times, even at the expense of wearing them out: forcing them to work more and earn less. Factory workers are often restricted to work on very specific tasks, with little visibility or impact on the final product. These workers are subject to job insecurity as their job depends on product demand, and if this is not enough, they are constantly threatened with offshore production-companies transferring manufacturing to countries with even lower costs of labor. Under these conditions, it is difficult to retain a sense of accountability and pride.

“Workers are largely considered inconvenient yet-to-be-robotized mules. The problem is not that humans make errors but that workers no longer care.”

Obviously not all manufacturers are like this. There are many that deeply respect their workers. We are all highly sensitive with news of manufacturers in certain regions exploiting their workers or plainly violating their human rights. Our experience at nFlux after working with select global manufacturers is that some are changing the game and care about workers, their working conditions and their lives.

In a world where 70%+ of manufacturing activities are executed by humans and the other 30%- are conducted by machines–operated and maintained by humans, not enrolling humans in the responsibility of striving for quality is costly. Making workers feel exactly like “just workers” disconnects them from quality in the same way that industrial manufacturing disconnects them from their craftspeople’s soul. The first reason for the quality paradox is not the fact that humans make errors but that workers no longer care.

Fierce competition makes Cost of Quality a key concern

This lack of deep accountability and pride from the workers forces manufacturers to implement a wide range of quality checks and mitigation activities. Industrial manufacturing stole craftsmanship’s soul away from workers in the name of productivity, only to generate a bigger problem: Cost of Quality.

Although companies can aim to produce high-quality goods, the cost of implementing the quality management measures activities generates a significant overhead on top of basic manufacturing costs. ASQ uses Cost of Poor Quality (COPQ) to talk about these costs which they classify in three types:

- Appraisal costs: those associated with measuring and monitoring activities related to quality

- Internal Failure costs: those incurred to remedy defects discovered before the product or service is delivered to the customer.

- External Failure costs: those incurred to remedy defects discovered by customers (also known as “Quality Escapes”).

Cost of Quality represents up to 20% – 30% of sales revenues in some industries. This is a major cost component and, as such, it is a very attractive cost component to experiment with in order to increase competitiveness. Manufacturers opt to statistically reduce the sampling frequencies in their quality controls, they omit a few tests and checks during design time, they increase tolerances of certain components, etc. All of these measures individually have potentially small impact on the final product quality, but all together can significantly compromise its quality.

“It is very attractive for manufacturers to experiment with quality management when trying to improve margins.”

There is also another way to reduce costs: experimenting with quality of materials and designs. Being less restrictive on tolerances, on material durability, and on design sturdiness. Caring less about how much products last, not only helps to reduce cost but to accelerate the pace at which consumers replace their products. Whether this is planned obsolescence, or simply fostered obsolescence, making durable products not only costs more, but also means selling less.

As such, the second reason for the quality paradox is that quality and durability are expensive to achieve, and companies are incentivized to push profitability above all else.

The average customer cares more about Price than about Quality

Historically, companies have mostly kept these experiments on quality and durability within ethical levels. There has always been the conviction that bad quality could destroy the reputation of a company, so manufacturers have taken controlled bets when it came to lowering overall product quality. In a way, the market has served as a control mechanism… but this has come to an end when some have started to smash the ethical boundaries of minimum quality levels only to realize that the market has reacted in the opposite direction.

Let’s face it. Consumers no longer buy products after careful in-person inspection or through word of mouth but under the influence of sophisticated marketing strategies and strong social pressure to keep up appearances (who is not influenced by Instagram or Tik-Tok?)

We also live in a time of ever-expanding technological change. The products we bought 5 years ago, for the most part, are dated… the ones we bought 10 years ago are completely obsolete. Society has shifted the focus away from wanting reliable and durable products and, instead, focused on having up-to-date, fully featured products, even at the expense of the environment. The WEEE (Waste Electrical and Electronic Equipment) Forum reported that every ton of e-waste releases two tons of carbon dioxide to the atmosphere, and that keeping the current trend, over 81 million tons of e-waste will be thrown out by 2030.

In this context, many traditional OEMs have been overtaken and disrupted by newcomers with no prior brand credibility and with products that have an objectively lower quality standard. From automobiles to clothing, from mobile phones to furniture. It is heartbreaking to decide what is worst, if seeing many beloved manufacturers die or seeing many other beloved manufacturers give up on their quality standards.

But the trend is clear. Democracy in the market has decided that having the latest and greatest is a must, that always having things to buy is fun and that price is king.

The return of the quest: Humans, Technology and Quality

Separating craftsmanship from labor has enabled humanity to progress faster than ever before, but this departure has generated a new set of problems, especially in a world that changes at a bewildering pace and in a society that no longer worships the same values as in the past.

At nFlux, we believe that the solution to these problems is largely connected with the restitution of humans and craftsmanship in labor. The solution to a rapidly changing world, where product designs constantly change, is not in further automation or in further optimizing the already automated parts of manufacturing, which is the goal of Industry 4.0. Rather, the solution that is going to bring manufacturing and humanity to the next era does not lie in further refining the machines but in leveraging new technologies to augment humans and enable the craftspeople of the future.

This is a subtle change in perspective that completely changes the paradigm of technology in manufacturing. Technological evolution in manufacturing should no longer be about continuing to replace humans with machines but about making technological solutions (machines, tools, services…) that give craftspeople more and better capabilities and skills.

This is not saying that robots, machines and technology are not important anymore. It is just changing the perspective and the priorities. Sustainable manufacturing is not about going back to the craft techniques of the past. We believe that robots, and machines in general, are not human replacements but human extensions. They enable the craftspeople of the future to produce things that they could not produce simply by using legacy hand tools.

nFlux is working on next generation human technologies, applying breakthrough Artificial Intelligence and Computer Vision techniques under this radically new paradigm where humans become the center and technology is used to make us better. This post is the starting point for a series of communications where nFlux is going to explain, in collaboration with our customers and partners, our vision for the future of manufacturing, the future of human technologies and how our current solutions are making future happen.Stay tuned https://www.nflux.ai/!